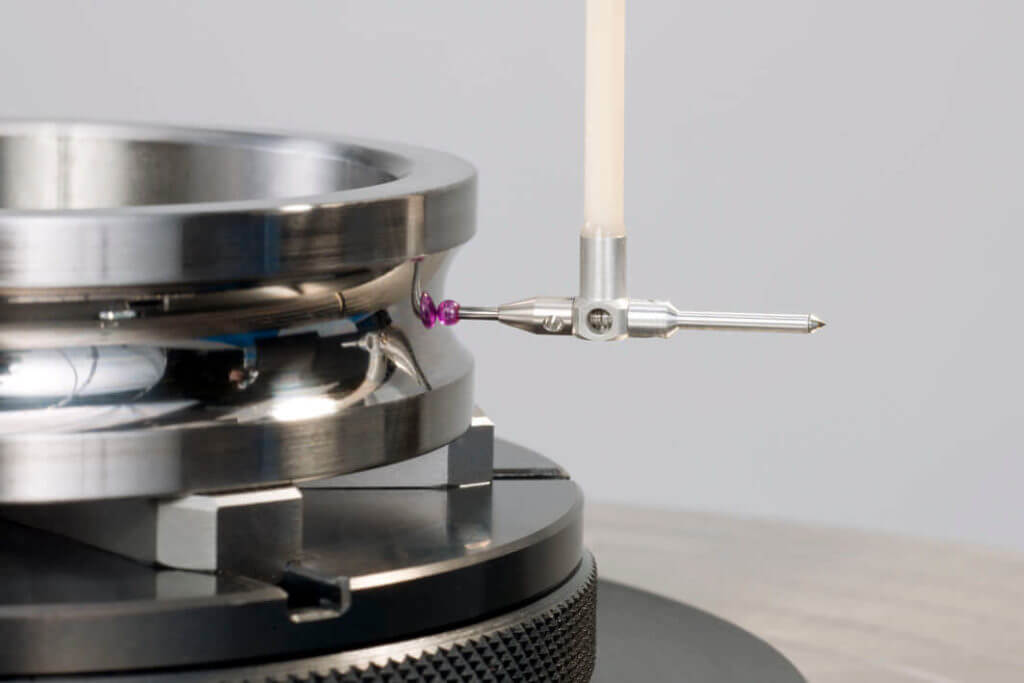

Milling is the machining process by particle separation (cutting) of prismatic parts of simple or complex geometry.

The ability to handle complex designs, angles, and difficult angles in one machine reduces the cost of tool making and working time, resulting in higher profit per piece, while maintaining the compliance of parts across the entire production series.

Our most modern Haas machines guarantee quality and precision.

Having machines such as 3-axis CNC milling machines we are able to process various types of materials (aluminum, wood, plastics, styrodur, etc.) of various dimensions and shapes.

Based on your models, designs and / or ideas, we process the material of maximum dimensions 1300 mm x 2000 mm x 100 mm.

Maximum part size – 1500 x 660 mm

Average part size - from 10 x 10 mm to 350 x 350 mm

Degree of complexity – medium and high

The materials we handle are aluminum (about 60%), plastics (about 15%), steel / stainless steel (approx. 15%), brass (approx. 5%), other materials (approx. 5%).

The cost of CNC machining is calculated on the basis of the time consumed and the type and thickness of the material.

If you are interested, send us your design blueprint, and we will answer you in the fastest possible time.